How to Start a Glass Recycling Business

When it comes to business and the environment, glass recycling is a win-win. Not only can a glass recycling business be highly profitable, but it also offers numerous environmental benefits such as repurposing tons of glass that may otherwise end up in landfills.

When deciding whether to start a glass recycling business one must consider a few key items. We outline those items below, but there may be more you need to know depending on your specific situation. If there is any additional information we can supply to help educate and better support you, please let us know by using our contact form.

Some important items to consider when starting a glass recycling business:

- Sources of glass – How much, what kind, and how will it get to your recycling location? Consider a charge to provide the service, or free at your “door/recycling location”.

- How much waste glass is available? What recycling programs are in place now? Can separation and collection programs be set-up for consumers, restaurants, businesses, etc.? Who would set these programs up and provide the service (at a fee) to place containers for the glass and bring them to the recycling center?

- Types of glass that can be accepted include bottles, plate glass, mixed color glass, and also ceramics. The glass may contain some non-glass residual.

- Location – Where can you locate the machine? Are any permits needed? Is it available and convenient for people and businesses to bring you glass?

- Need a concrete pad and three phase power. A bunker to drop-off the glass, and a loader to pick up and put in the surge hoper. The GP-Mini and GP-MegaMini are hand fed or fed with a barrel or small box tipper. Our large systems include a 4 ton surge hopper for loading the systems.

- Can be located outside, but good if there is a rain/sun roof, and windbreak.

- Not very noisy. The glass being deposited in the bunker or surge hopper is the loudest intermittent noise.

- Dust is controlled with a misting system. The glass dust is not crystalline silica or have any negative impact on your health.

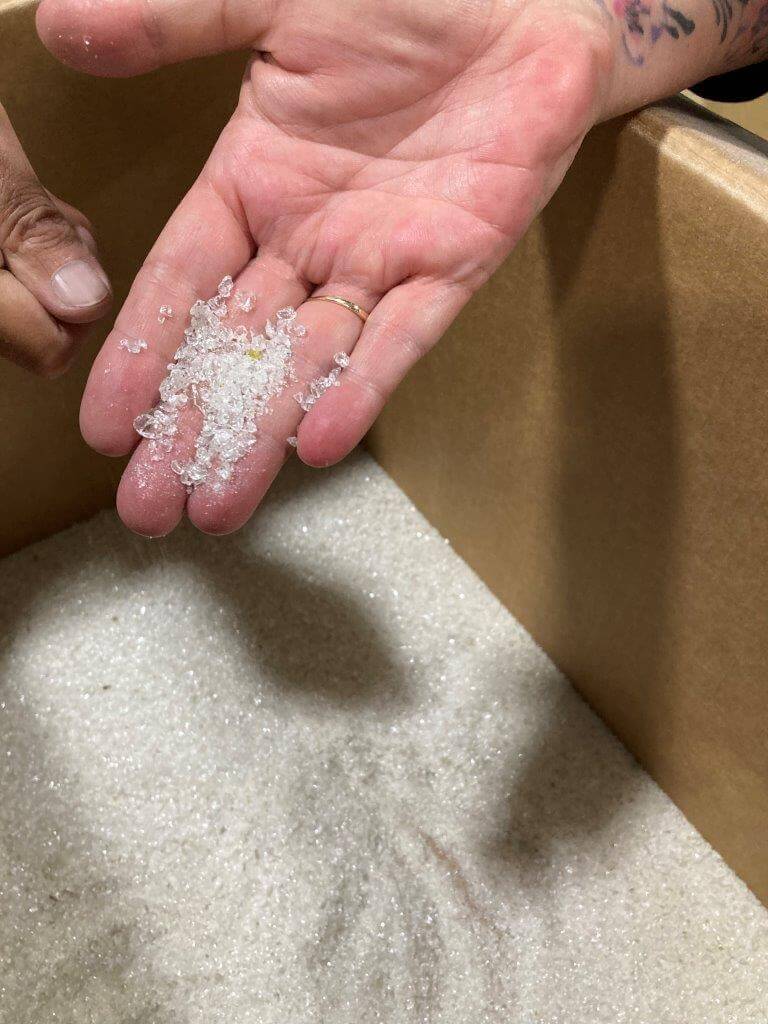

- Technology – The Andela Glass Pulverizer and Glass Crusher Systems will process all types of glass, no sorting or pre-cleaning needed, and the finished product is a crushed sand cullet, or glass sand and aggregates with rounded edges.

- Andela Products offer a full line of crushers, pulverizers, trommel screens, conveyors and hoppers. The individual components are put together to make a turn-key system for each customer to their operational parameters. The systems are designed to make a crushed glass cullet, a glass “stone”, or glass sand.

- Funding – Can you get community support and funding to make this possible? Private donations? Grants? Loans? Investors? Leasing options are available. Incorporate into an existing or new recycling system.

- Markets – Sell the pulverized glass as sand or aggregate in your community. Implement a “scoop your own” program. The community will pay $5.00 – $10.00 a 5 gallon bucket and bring it back for their home projects (landscaping, glass mulch, play sand, etc.). You can also dry and screen to make a sandblasting abrasive. Also use Andela systems designed to produce glass cullet or glass feedstock for manufacturing into new bottles or fiberglass. Additional uses are listed below.

Uses for crushed glass aggregate and glass sand

To expand on the potential markets for crushed / pulverized glass we put together a short list of some common uses. Our machines can produce glass aggregate in various sizes, from furnace-ready cullet to fine sand. You’ll want to know your end uses before purchasing a glass crusher or glass pulverizer, as different machines are best suited to produce particular sized aggregate. There are also some machines which can produce a range of aggregate sizes. At Andela Products, we can help you select the best glass recycling machine for your needs. Some common uses for crushed glass include:

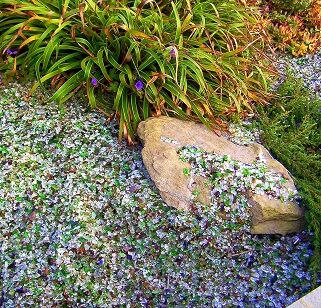

- Mulch for various landscaping applications. It is attractive and never rots or breaks down – long lasting.

- Glass sand retains moisture on the particle surfaces. It holds the moisture below the surface and is available for the plant’s roots.

- Glass mulch keeps insects, slugs and other pests from coming up to the plants. It also never fades or rots – long lasting.

- Glass is an insulator, so it creates an insulated layer of mulch to protect the plant’s roots from extreme temperatures.

- Mix glass sand with compost to make a soil blend that includes organic nutrients from the compost and filtration and water retention from the glass sand.

- Amorphous silica – it is safer to use than regular sand.

- Filtration aggregate – it is angular sand, but not sharp. The water flows through it faster than natural aggregates. (Good for pipe bedding, septic filter sand, etc.)

- Fine glass particles are a substitute for Diatomaceous Earth (DE). It has the same chemical structure as DE and is an organic pesticide. (The fine glass dust sucks the moisture out of insects)

- Concrete products – use only the sand size, and make a stronger concrete product.

- Construction sand or aggregate replacement in any building or construction applications.

Build a glass recycling system specific to your needs

At Andela Products, we have different system sizes and configurations depending on the type of glass you will be putting into the system, how much you need to process, and what the final product specifications might be for your market.