Output Sized Glass

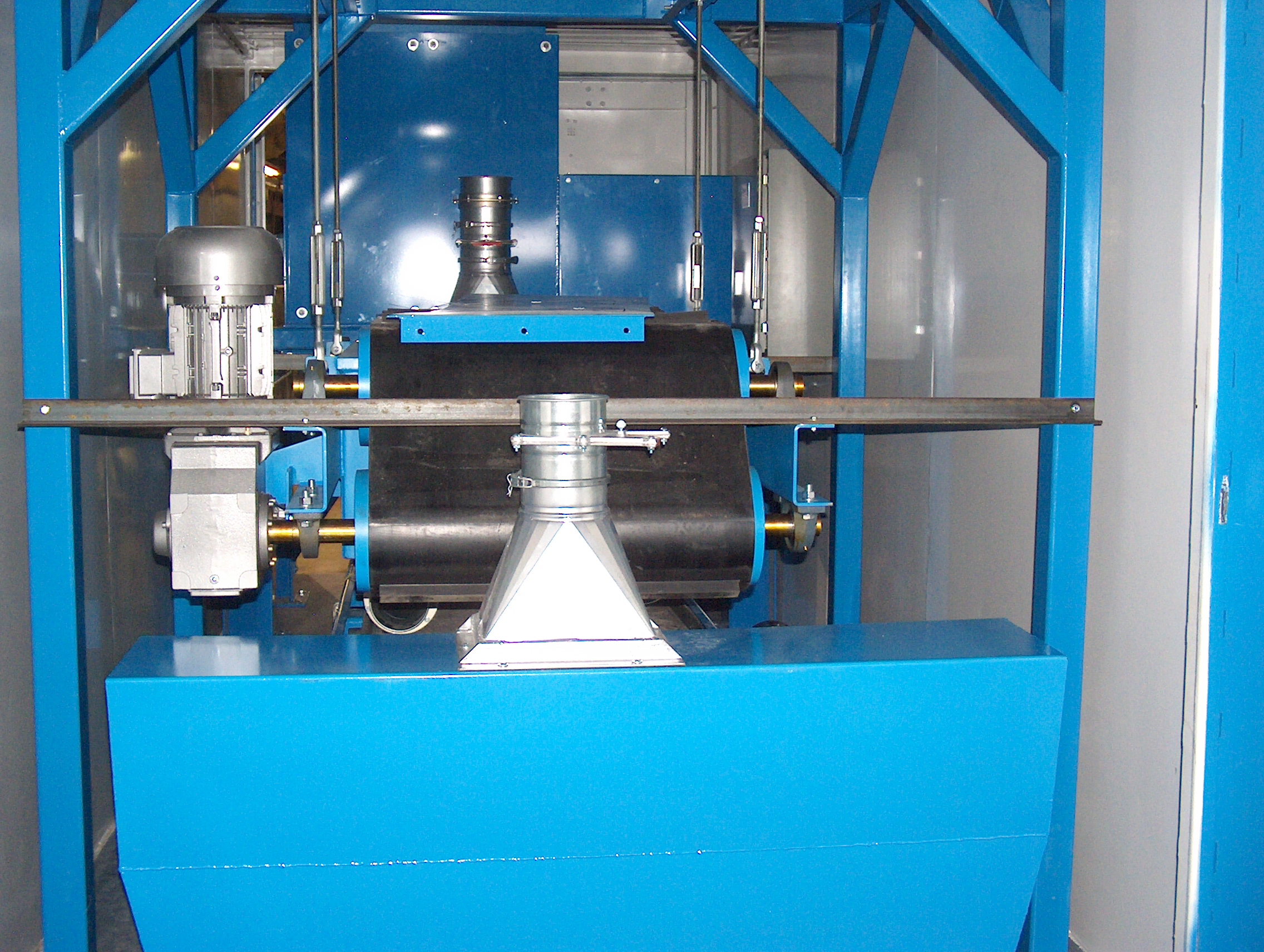

The CRT-20′ crusher discharges a 6″ minus glass cullet. The larger ferrous metal pieces are separated out. The CRT-40′ pulverizer unit reduces the 6″ minus glass cullet down to 1/4″ minus pulverized glass.

Components

The CRT-20 crusher module system will discharge the processed material from the sides of its 8′ wide x 9′ high x 20′ long container. The self-contained system is placed on a steel structure to achieve efficient material handling flow of the infeed and discharged materials.

The Andela CRT Recycling System comes complete with its own dust collection system and will process approximately 600 CRT tubes an hour. The CRT-20′ Crusher Module Includes an infeed conveyor, CRT Crusher, conveyor, and cross-belt magnet, container and dust collector. The CRT-40 Module includes an Andela Pulverizer, trommel, and conveyors all contained in a container. Loading, unloading or stacking conveyors are available options.

Not sure what you're looking for? Please use our application chart to find the right system for your business needs.

CRT 20

The Andela CRT-20 Recycling System uses patented “flailing-arm” hammers to break CRT tube glass while leaving internal ferrous metal frames whole for separation. At the end of 20’ container, ferrous metal is removed and crushed glass exits the conveyor. The container, with dust extraction, captures phosphor and dust. Combined with the Andela AGB-2 Glass Crusher System, CRT tube glass is crushed into approximately 6” minus glass. Larger pieces of glass – mostly panel glass – is separated for ease of picking and removal.

CRT 40

After CRT tubes are processed with the CRT-20 system, the crushed glass cullet can then be pulverized. A Glass Pulverizer System with CRT-40 container pulverizes funnel/panel/mixed glass mix into “sand” or “gravel” sized product. All non-glass residue is separated. The entire system is containerized for dust collection.

Shop Individual Components

Not looking for a complete system? We also offer individual system components.

Why Choose Andela Products

- A global company with sales throughout the United States, Canada, Japan, Spain, France, and more

- Custom-built machines to your organization's specific needs

- Durable and built to last longer than competitor machines

- Built-in safety features to ensure proper machine use