Andela Glass Crushers vs. Andela Glass Pulverizers

Do I Need a Glass Crusher or Glass Pulverizer?

Many of our prospective customers think they need a “crusher” when they need a “pulverizer.”

Both Andela crushers and pulverizers break down glass using mechanical force via our flexible impactor system. Understanding the difference between crushers and pulverizers is essential. Input, output, and end-uses for your recycled glass are the deciding factors.

Regardless of which system you purchase, recycling glass is environmentally responsible and economically beneficial.

What is a Glass Crusher?

Andela glass crushers are machines designed to break down glass items (such as bottles, jars, and glassware) with mechanical force, resulting in irregularly shaped pieces of glass, also known as glass cullet.

Andela Glass Cullet

Our crushers sort, clean, and crush. Crushing glass into cullet greatly reduces the volume and therefore the transportation costs incurred by shipping glass to manufacturers.

Our crushers sort, clean, and crush. Crushing glass into cullet greatly reduces the volume and therefore the transportation costs incurred by shipping glass to manufacturers.

Bottlers add recycled glass cullet to their smelters to conserve virgin raw materials, lower energy consumption, and reduce greenhouse gas emissions. Recycled glass cullet also melts at a lower temperature, reducing the energy needed, and the harmful byproducts created, by the smelting process.

Another valuable use for glass cullet is as feedstock for fiberglass manufacturing. Fiberglass manufacturers have strict specifications for moisture level, size of grain, color distribution, and level of contaminants in cullet. Reaching the ideal consistency requires investments in the proper equipment. (Note that some fiberglass manufacturers prefer glass sand.)

What is a Glass Pulverizer?

Andela glass pulverizers break down glass using our flexible impactor system calibrated to produce uniform sand and/or gravel-sized pieces suitable for replacing ecologically damaging mined and dredged aggregates or soil amendments.

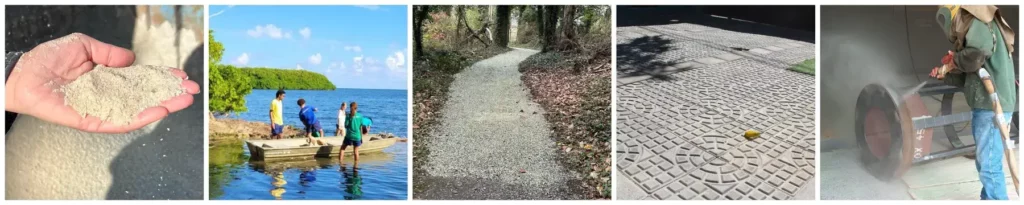

Andela Glass Aggregates: Sand and Gravel

- Andela glass sand

- Andela glass gravel

Pulverized glass aggregates are used as a substitute for traditional sand or gravel in various construction and landscaping applications. It replaces construction sand, can be used in concrete products, asphalt applications, and landscaping. Benefits include lighter weight and longevity.

Glass sand as a glass “mulch”, or mixed with compost and/or soils, has natural pest-repellant properties, the ability to hold moisture between rain events, and it percolates two times as fast as regular sand, improving drainage and reducing runoff.

While this list contains some popular end uses it is by no means exhaustive. Refer to our comprehensive review on uses for crushed glass aggregate for even more ideas.

Which Andela System is best for your application?

| Pulverizer System | Crusher System | Windshield System | CRT Recycling System | Single Stream Recycling | CleanGlass Cleanup System | ||

|---|---|---|---|---|---|---|---|

| Glass | X | X | X | X | X | X | |

| Ceramics | X | X | X | ||||

| Type of Glass Processed | Windshields | X | |||||

| CRT Tubes | X | X | X | ||||

| Other for Product Destruction | X | ||||||

| 6" Minus | X | ||||||

| 2" Minus | X | ||||||

| Sized Aggregate Produced | 3/4" Minus | X | |||||

| 3/8" Minus | X | X | X | X | |||

| 1/4" Minus | X | X | X | X | |||

| Abrasives | X | X | X | ||||

| Landscaping | X | X | |||||

| Market | Glass Products / Furnace Ready Cullet | X | |||||

| Filtration | X | X | X | X | X | ||

| Fiberglass | X | X | X | X | |||

| Aggregate | X | X | X | X | X | ||

| Composite Products | X | X | X | X | X | ||

| System Spec Sheets |

- Andela AGC-1 Glass Crusher

- Andela GP-1HD Glass Pulverizer and Surge Hopper

Still Not Sure Which to Choose? – Ask Our Team of Glass Recycling Experts

For help choosing between an Andela glass crusher or glass pulverizer, reach out to our team of experts.

We provide glass recycling solutions uniquely tailored to entities all over the world, from bars and restaurants to commercial recycling centers supporting municipalities and governments.