Why is Crushed Glass the Sustainable Solution to Creating Pavers?

STRONG

Mixing crushed glass sand with a binding material made from mixed plastics makes for durable pavers.

VISUALLY APPEALING

A variety of colors, sizes, and textures are available, allowing for creative patterns.

SUSTAINABILITY

Environmentally friendly choice reducing plastic waste and diverting glass from landfills.

THE PROBLEM

Traditional Pavers Require A Large Amount of Energy and Resources To Produce

Waste Glass And Plastics Go Unrecycled In Remote and Island Locations

There is a solution for this problem. Turn them into building materials that can be used locally! More than 5 trillion tons of plastic are littering roads and floating in our oceans, and beach pollution comprised of plastics and waste glass exceeds 6 billion tons. Any useful thing made from these two ingredients is a win-win!

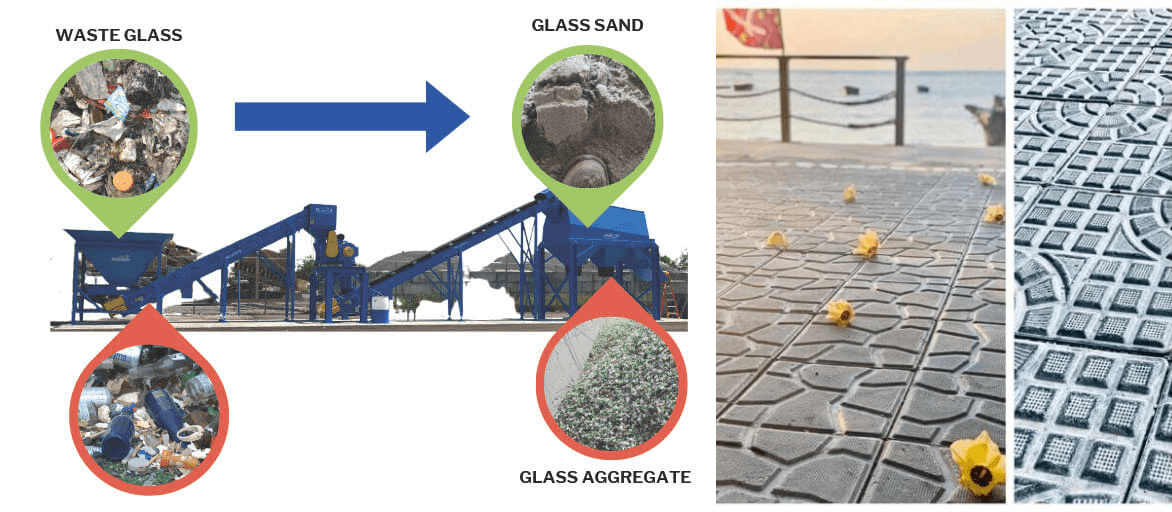

Glass, as opposed to plastics, is endlessly recyclable. Andela pulverizers create clean glass sand that can be mixed with shredded plastics to create recycled plastic and glass pavers — a beautiful solution.

THE SOLUTION

ADDING GLASS SAND TO SHREDDED PLASTIC IS A SUSTAINABLE SOLUTION FOR PAVERS

Pulverized glass combined with a shredded plastic mix creates a lighter, stronger, and more durable paver. First, shredded plastics are safely heated to make a polymer binder in place of cement and water, then glass sand is mixed in. This mix is pressed by molds into decorative paver shapes and other useful shapes such as for curb construction. The pavers use up to 50% recycled glass sand/aggregate per volume which provides the structure, strength, and durability required.

Variety of Design

The plastics glass mix is made into a variety of designs using presses and custom-made molds. Permeable pavers, decorative patio blocks, or interlocking road pavers are all available. A variety of surface construction designs are possible.

How Is Glass Aggregate Used to Create Pavers?

To create plastic and glass pavers, follow these steps:

- Pulverize glass using the Andela glass pulverizer unit or system.

- Shred mixed plastics into little chips.

- Mix the glass aggregate and shredded plastic chips.

- Pour them into the extruder.

- Take the melted plastics and glass mix and put into the mold and press.

- Cool it off in water and you have the finished product.

A SUCCESS STORY

Caltech Created Pavers, Bricks, Building Blocks, and Curb Units Using Crushed Glass

Tons of Waste Glass and Plastic Bottles Diverted From Landfill

Co-founder and CEO Jean Vezina leads Caltech’s growing environmental services portfolio. Processes in development enable communities worldwide to recycle their waste on location, drastically reducing waste and environmental damage while generating employment opportunities for some of the most vulnerable populations. Central to their commitment is upskilling local workforces to international standards, focusing on safety, environment, quality, and innovation.

Mixing recycled glass and recycled plastic bottles to create pavers is just one of their groundbreaking processes! Caltech uses Andela Products Mega-Mini glass pulverizer to produce the glass sand used in the mix. So far, they have created pavers, bricks, building blocks, and curb units.

“The Andela (GP-Mini) machine works without fail, every day. Love the simplicity and robustness of it. The resulting sand can be used in construction or in landscaping. Indeed, do not turn glass into the trash, turn it into a usable (and valuable) product.”

- Jean Vezina, CEO - Caltech Group

Jean Vezina, CEO of Caltech Group in Timor-Leste, initiated a process for producing viable products combining waste glass and plastics. Check out their groundbreaking efforts and results.

"16T of glass were recycled on this project alone in the form of recycled glass sand incorporated in our pavers - your Andela Products GP mini is a real workhorse!" Read More About the GP Mini

Millions of plastic water bottles Recycled in Timor-Leste.

In Timor-Leste hundreds of tons of plastic waste is generated each week. Caltech has helped manage waste by recycling plastic to create pavers, bricks, building blocks and curb units. Since 2019, over 7 million plastic water bottles have been recycled, resulting in the production of 12,000 recycled plastic and glass pavers.

The Future of Sand is Glass Aggregate. Get In On The Action.

Why should I invest in a glass crushing machine?

- The demand and popularity for crushed glass is rising

- These machines are easy to use

- The versatility of the end-uses makes them a worthwhile investment

Where Can I Begin?

Andela’s innovative glass recycling systems help create durable and appealing pavers used in construction projects. We will help you find the perfect system for your specific needs.

Frequently Asked Questions

Crushed Glass and Glass Aggregate Serve A Variety of Other Applications in Construction, Gardening, Community Projects and More.

Wondering about the other uses for glass sand aggregate?

Glass sand aggregate has many uses for individuals and businesses. With no sharp edges, it is easily handled and appropriate for even the most delicate applications such as play sand for children. Glass aggregate can be produced in different sizes and gradations as needed.

| • Coastal Restoration • Soil Amendments • Hydroponics • Play Sand • Glass and Plastic Pavers |

• Rain Gardens • Pipe Bedding • Polished Concrete • Formed Polymer Concrete • Pavement Concrete Blocks |

• Coastal Restoration

• Soil Amendments

• Hydroponics

• Play Sand

• Glass and Plastic Pavers

• Rain Gardens

• Pipe Bedding

• Polished Concrete

• Formed Polymer Concrete

• Pavement Concrete Blocks