Why Use Glass Sand for Construction?

Reduces carbon footprint

as a local sand resource

meets size spec and gradations

of typical construction sand

avoids destructive impacts

of sand dredging and mining

THE PROBLEM

Mined and Dredged Construction Sand Creates Environmental Damage

Sand is the foundation of construction and a fundamental ingredient in concrete, asphalt, and other building materials. Because of this, sand is the second most used resource on Earth, after water. With 50 billion tons (and growing) of sand extracted from lakes, riverbeds, coastlines, and deltas, each year, the ecological and societal consequences are massive. Sand demand is projected to rise by 45% over the next four decades.

THE PROBLEM

Dredging and Mining Sand Impact List

Soil erosion, damaged aquifers, loss of coastal protection from storm surges, and damaged biodiversity with negative impacts on food production, fisheries, and tourism.

An International Problem

International demand for construction sand has tripled in the past two decades, reaching 50 billion tons (and growing) each year. As a commodity, sand is becoming harder to safely source, leading to ecological impacts and the creation of criminal enterprises, one of which consists of “Sand Mafias”. The United Nations calls sand mining and dredging an international crisis, in the top three — after money fraud and illegal drug trading.

THE SOLUTION

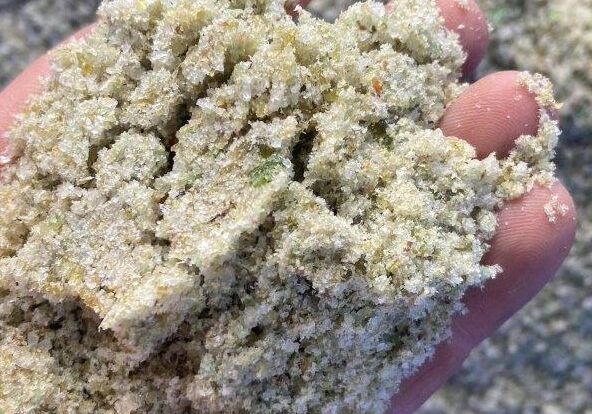

Pulverized Glass Sand

While pressure on governments to regulate sand mining is increasing, more must be done to find alternatives. For instance, recycled glass waste can be pulverized and implemented in many construction applications, replacing mined and dredged sand.

Glass sand is a great sustainable alternative to natural sand because of its similar engineering characteristics. For example, the chemical composition of sand and crushed waste glass is similar — both largely consist of silica. And, because glass is produced by melting sand, the densities (how tightly particles can be packed together) achieved by mined sand and recycled glass sand are similar. While sand and crushed waste glass have certain characteristics in common, they also differ. For example, beach sand particles are typically more rounded than crushed waste glass particles. The angular shape of glass sand particles makes them interlock more easily, which increases their construction strength. Also, waste glass can be crushed to varying particle sizes. This is important because engineering characteristics of building materials differ with different particle sizes.

Applications of Glass Sand in the Construction Industry

- Bedding

- Backfilling Material

- Concrete

- Road drainage

- Embankment Fill

- Landscaping

A SUCCESS STORY

Orcas Recycling Services Success Story

Why should I invest in a glass crushing machine?

- The demand and popularity for crushed glass is rising

- These machines are easy to use

- The versatility of the end-uses makes them a worthwhile investment

- Environmental protection and restoration

Additional Information

- Recycled Glass, Turned into Sand, Is Restoring Louisiana’s Coastline

- Tulane scientists and engineers to use recycled glass ‘sand’ to prevent coastal erosion

- Glass Half Full’s fight against coastal erosion

- Restoring Coastlines and Wetlands Using Recycled Glass

- Glass to grass: Can crushed glass help restore Cayman’s coastal environment?

- A new initiative to turn glass bottles from New Orleans’ many drinking spots into tiny particles of sand has raised hopes. Can recycled glass help restore Louisiana’s eroding coastline?

The Future of Sand is Glass Aggregate. Get In On The Action.

Andela’s innovative glass recycling systems create glass aggregate with numerous uses, including construction sand. We will help you find the perfect system for your specific needs.

Frequently Asked Questions

Crushed Glass and Glass Aggregate Serve A Variety of Other Applications in Construction, Gardening, Community Projects and More.

Wondering about the other uses for glass sand aggregate?

Glass sand aggregate has many uses for individuals and businesses. With no sharp edges, it is easily handled and appropriate for even the most delicate applications such as play sand for children. Glass aggregate can be produced in different sizes and gradations as needed.

| • Coastal Restoration • Mulch • Glass Based Soil • Hydroponics • Play Sand • Glass and Plastic Pavers |

• Rain Gardens • Pipe Bedding • Polished Concrete • Formed Polymer Concrete • Pavement Concrete Blocks |

• Coastal Restoration

• Mulch

• Glass Based Soil

• Hydroponics

• Play Sand

• Glass and Plastic Pavers

• Rain Gardens

• Pipe Bedding

• Polished Concrete

• Formed Polymer Concrete

• Pavement Concrete Blocks