Why Is Glass Sand A Smart Choice For Concrete Products?

community friendly

Increases community recycling and reduces the volume of waste glass going to local landfills

Local Resource

Pulverized glass sand is environmentally friendly and engenders a lower carbon footprint than most construction materials

Relevant Engineering Characteristics

Pulverized glass sand meets the performance requirements of natural construction sand used in certain concrete products such as concrete blocks

THE PROBLEM

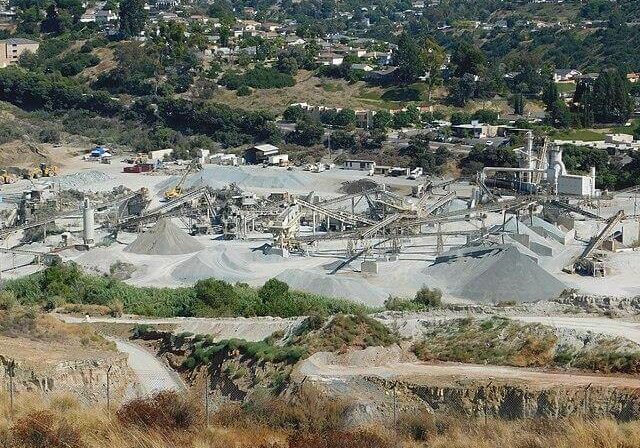

Sand Is A Finite Resource

Believe it or not, sand is a finite resource that causes great ecological harm when mined or dredged for concrete products.

The Rate of Sand Extraction is Environmentally Unsustainable

However, construction sand used to make concrete blocks is also used in a great and growing number of other construction applications. Sand is so important to construction that the mining and dredging of sand has spiraled out of control, increasingly damaging ecology and economic stability. For context, in 2023 the 3,400 US-based companies produced 920 million tons of construction sand and gravel, operating 6,500 pits in 50 States. This rate of extraction is environmentally unsustainable and is causing severe socio-economic consequences, including:

- Habitat loss: Sand mining can destroy habitats and ecosystems, especially aquatic ones.

- Air and water pollution: Sand mining can release silica dust into the air, which can cause lung cancer and other respiratory diseases in miners and nearby residents. The mining process can also pollute waterways.

- Erosion: Sand mining can cause erosion that removes protection against coastal hazards like hurricanes and extreme waves. It can also threaten critical infrastructure like roads and railways.

- Water security: Sand mining can change how waterways flow and flood, lower groundwater capacity, and deepen rivers and estuaries. This can lead to saline-water intrusion from the sea and raise water costs for local communities.

- Tourism: Sand mining can damage coastal scenery, which is important for tourism.

THE SOLUTION

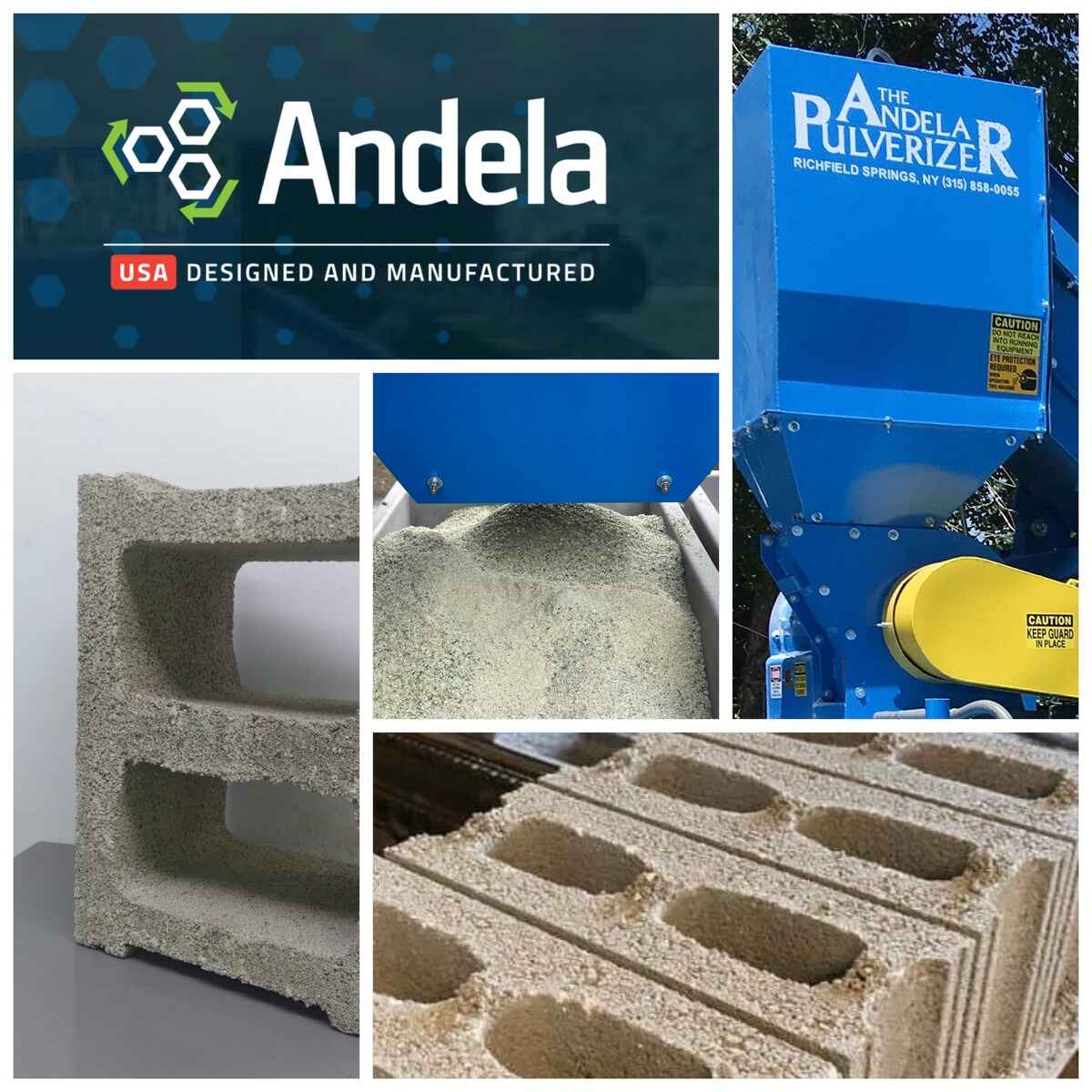

Glass Sand Processed by an Andela pulverizer!

Post-consumer glass processed with an Andela Products pulverizing system can be a valuable supplementary material in concrete products. This approach not only diverts glass from landfills but also reduces the need for mined and dredged sand in concrete block mixes, thereby decreasing the environmental damage, energy consumption, and carbon emissions associated with the transportation of mined/dredged sand.

A SUCCESS STORY

Bloques Caribe, a construction company, uses natural sand, stones, cement, water, and pulverized glass to make their concrete blocks.

Our customer in Puerto Rico, Bloques Caribe, a construction company, uses natural sand, stones, cement, water, and pulverized glass to make their concrete blocks. Each block weighs 28 pounds and is made with approximately 10% to 15% glass sand without losing strength. José Mercado Quintana, the Bloques Caribe Inc. (BC) administrator in Guaynabo, Puerto Rico, keeps his company on the forefront of using glass in the cement mixture for environmental and economic purposes. One company calculation estimated that Bloques Caribe Inc.’s annual savings for substituting glass into their cement block mixture is approximately $507,892, based on the weight of an 8”x8”x16” block and the estimated 11% glass in weight per block.

Concrete Blocks Are Strong, Durable and More Affordable Than Bricks

Concrete blocks are an important construction material because they are strong, durable, and can be used for many purposes:

- Strength: Concrete blocks can support heavy structures and are often used for load-bearing walls, foundations, and retaining walls.

- Durability: Concrete blocks are resistant to fire, high winds, rotting, and weathering, and require minimal maintenance.

- Cost: Concrete blocks are usually more affordable than bricks.

- Speed: Concrete blocks are larger and faster to install than other materials, which can help meet project deadlines.

- Insulation: Concrete blocks can provide good thermal and sound insulation.

- Environmental impact: Concrete block construction can reduce labor, transportation costs, dust, and noise pollution from heavy machinery.

- Design flexibility: Concrete blocks come in many shapes and sizes and can be used for a variety of purposes, including floors, walls, and roads.

Stats from: Glass Recycling in Caño Martín Peña (wpi.edu)

$507k

annual savings

$0.05

saved per block in raw material costs

1496g

made of glass in a 8"x8"x16" block

$507k

annual savings

$0.05

saved per block in raw material costs

35+ volunteers

made of glass in a 8"x8"x16" block

The Future of Sand is Glass Aggregate. Get In On The Action.

Why should I invest in a glass crushing machine?

- The demand and popularity for crushed glass is rising

- These machines are easy to use

- The versatility of the end-uses makes them a worthwhile investment

- Environmental protection and restoration

Where Can I Begin?

Andela’s innovative glass recycling systems create glass aggregate with numerous uses, including durable concrete blocks used in construction projects. We will help you find the perfect system for your specific needs.

Frequently Asked Questions

Crushed Glass and Glass Aggregate Serve A Variety of Other Applications in Construction, Gardening, Community Projects and More.

Wondering about the other uses for glass sand aggregate?

Glass sand aggregate has many uses for individuals and businesses. With no sharp edges, it is easily handled and appropriate for even the most delicate applications such as play sand for children. Glass aggregate can be produced in different sizes and gradations as needed.

| • Coastal Restoration • Mulch • Glass Based Soil • Hydroponics • Play Sand • Glass and Plastic Pavers |

• Rain Gardens • Pipe Bedding • Polished Concrete • Formed Polymer Concrete • Pavement Concrete Blocks |

• Coastal Restoration

• Mulch

• Glass Based Soil

• Hydroponics

• Play Sand

• Glass and Plastic Pavers

• Rain Gardens

• Pipe Bedding

• Polished Concrete

• Formed Polymer Concrete

• Pavement Concrete Blocks