What Is An Andela Clean Glass Plant?

An Andela Clean Glass Plant (CPG)

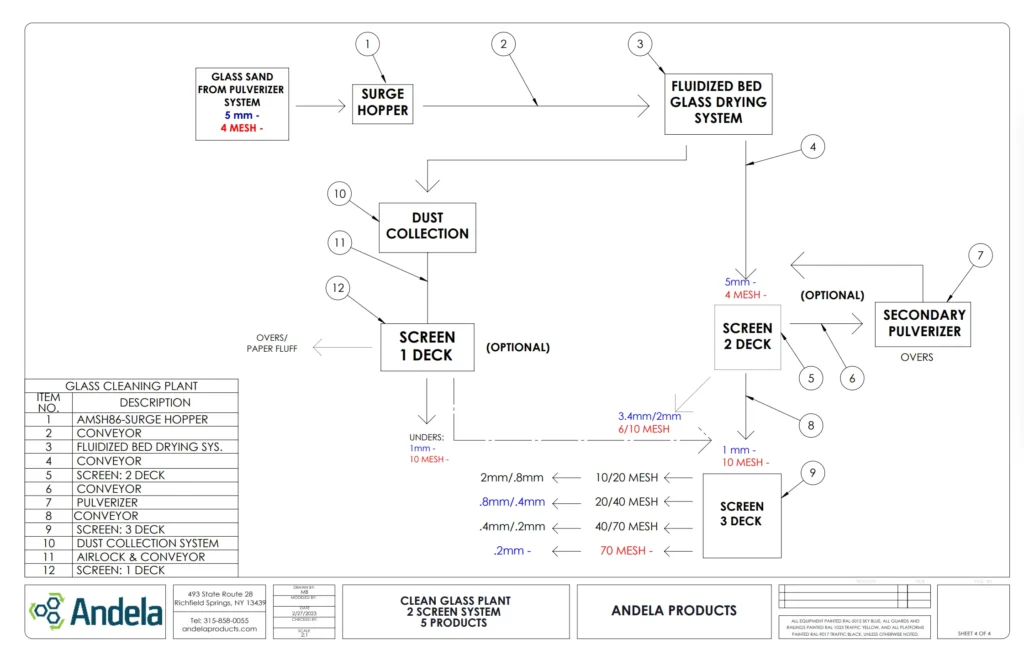

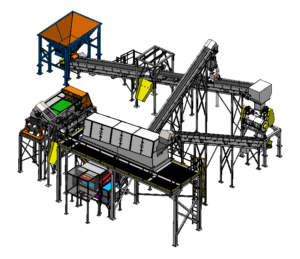

includes an Andela Glass Pulverizer combined with an Andela Glass Clean-Up System.

Clean Glass Plants include drying, screening, and re-grinding processes to turn MRF (Material Recovery Facility) glass into clean glass products (“Outputs”) for further refinement.

MRF glass includes broken glass, flattened metals, plastics, and shredded paper.

An Andela CGP utilizes selective reduction technology which leaves the non-glass residue, typical of MRF glass, in a larger form that exits the system as “Overs.”

The glass products of an Andela CGP are ready to be shipped to bottle, fiberglass, foam glass, or pozzolan manufacturers, or used for glass abrasives and filtration media.

What end products Andela customers choose for their markets depends on the location of their end-user relative to their plant, and the highest and best use of the outputs.

Andela Clean Glass Plants Include:

Hopper, Pulverizer, Trommel screen, Blower/Density Separator, Eddy Current, Conveyors, Dryer, and Screeners, integrated into a complete turnkey solution.

Outputs

- Glass Sand – less than 4 mesh (3/16”) without sharp edges. Meets specifications for regular construction sand.

- Glass Cullet/Aggregate – between 3/16″ – 1/2″ in size. Rounded edges. Can be re-circulated to make all sand.

- Overs – primarily non-glass, larger than 1/2″, consisting of plastics, paper, metals, etc. Plastics and metals may be further separated for their markets.

Learn more

Momentum Recycling in Utah has an Andela Clean Glass Plant.